Paywelder Hybrid System

Paywelder Hybrid System

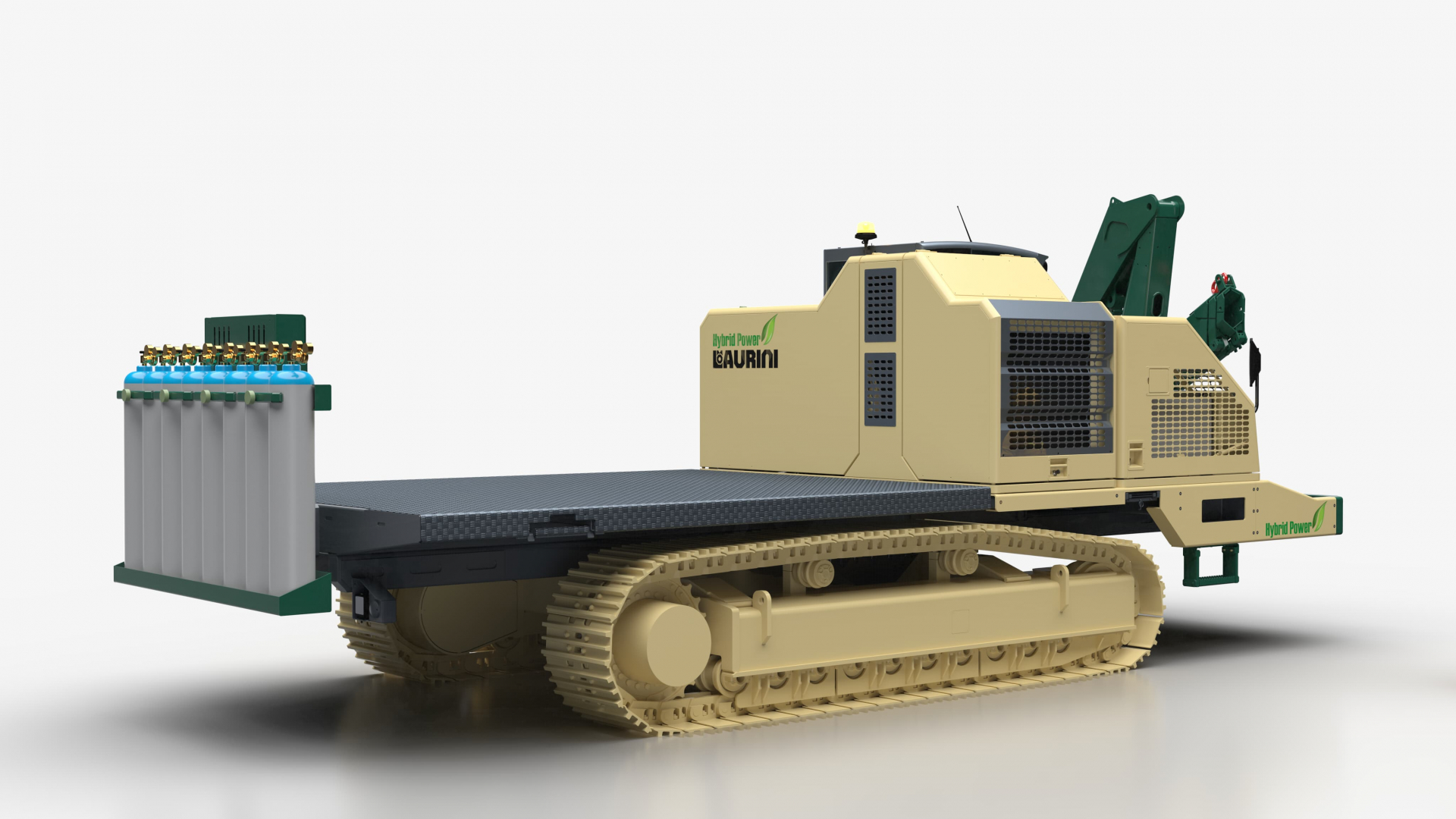

Flodraulic was commissioned by one of its long-standing customers to manage the design, supply, and field validation of a hybrid propulsion system for one of the company’s flagship machines — a r, a type of machine designed for welding pipelines in the pipeline industry.

The traditional machine features the installation of an internal combustion engine dedicated to traction and a genset for powering the welding systems. The revolutionary idea was to keep the genset as the sole source of electrical energy, replacing the combustion engine dedicated to traction with another electric motor. The ultimate goal is of course to bring significant benefits in terms of fuel consumption and emissions for the company that owns the paywelder, as well as for the operators using it.

Considering the system requirements of the paywelder, Flodraulic designed and supplied a serial hybrid system in which the generator for the welding system also provides power — as mentioned — to the traction system and auxiliary systems via a 500 V nominal Editron electric motor. This motor is controlled by a group of Editron inverters, while the control logic is managed by a control unit. The custom software communicates with the inverters to ensure optimal power management and full safety dynamics of the machine. The hydraulic traction system includes a closed-circuit system that interacts with the control unit to optimize the rotational speed of the electric motor and maximize overall system efficiency. Likewise, management extends to the fixed-displacement pumps for controlling auxiliary functions. The first field tests showed that the innovation introduced by Flodraulic for this type of machine helped reduce fuel and energy consumption while minimizing emissions and noise levels to the benefit of the operators.

The implemented solution also provides for less expensive scheduled maintenance compared to traditional systems, with significantly reduced machine downtime.

Efficiency elements

The hybrid system for the paywelder designed and implemented by Flodraulic in serial hybrid mode can be powered by any generator that meets its power and voltage requirements. The selected Editron electrical components — in particular the motor and inverters — are specifically designed for mobile machinery and feature structures engineered for high resistance to mechanical shocks and vibrations, with a high degree of IP protection.